Type TTK VK E1V

Steam turbines of type TTK VK E1V are robust and reliable vertical Curtis wheel steam turbines intended for pump drive, with oil tank and reduction gears as constituing components of the turbine.

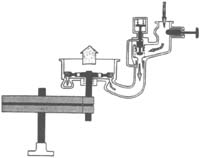

Turbine Works also delivers a water separator on live steam piping before the inlet of steam into turbine to protect the turbine from possible water droplets.

|

Type

|

Casing type

|

Power at coupling

(kW) |

Inlet steam pressure*

(bar) |

Steam

temperature |

Specific steam consumption

(kg/kWh) @04 bar abs |

Speed (RPM)

|

|

|

Rotor

|

Reductor

output** |

||||||

|

TTK VK 0.20 E1V

|

I

|

up to 200

|

15,5 bar abs

|

dry saturated

|

12.65

|

10.000 max

|

1100-1800

|

|

TTK VK 0.40 E1V

|

200-400

|

15,5 bar abs

|

dry saturated

|

12.20

|

10.000 max

|

1100-1800

|

|

|

TTK VK 0.63 E1V

|

400-800

|

15,5 bar abs

|

dry saturated

|

11.65

|

10.000 max

|

1100-1800

|

|

|

TTK VK 0.8 E1V

|

800-1100

|

15,5 bar abs

|

dry saturated

|

11.06

|

10.000 max

|

1100-1800

|

|

|

TTK VK 0.8 E1V

|

II

|

800-1100

|

15,5 bar abs

|

dry saturated

|

11.06

|

10.000 max

|

1100-1800

|

|

TTK VK 1.35 E1V

|

1100-1400

|

15,5 bar abs

|

dry saturated

|

11.04

|

10.000 max

|

1100-1800

|

|

|

TTK VK 1.60 E1V

|

1400-1600

|

15,5 bar abs

|

dry saturated

|

11.04

|

10.000 max

|

1100-1800

|

|

|

TTK VK 1.80 E1V

|

1600-2000

|

15,5 bar abs

|

dry saturated

|

10.95

|

10.000 max

|

1100-1800

|

|

| * Construction allows for inlet pressure up to 20 bar abs ** Depending on gear ratio |

|||||||

Turbine rotor consists of individual robust blades, individually machined, polished and controlled to allow for better performance and efficiency. Such construction alows for easy replacement of blades in case of rotor damage, without the neccessity for replacement of complete rotor with reduction gears pair.

DISTINCTIVE ATTRIBUTES

- Turbine and reduction gear casings are made out of quality steel and iron castings, providing robustness and greatly extending turbine worklife.

- All turbine components are designed so that turbine witstands possible sudden variations in load.

- Turbine parts are manufactured to extend turbine longlivety and reduce maintenance.

|

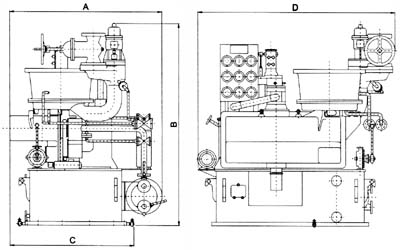

OUTLINE DIMENSIONS

|

|||||

|

|||||

|

CASING

TYPE |

~ DIMENSION (mm)

|

WEIGHT (kg) |

|||

|

A

|

B

|

C

|

D

|

||

|

I

|

1435

|

2340

|

1130

|

1950

|

3450

|

|

II

|

1700

|

2243

|

1400

|

2150

|

3800

|

Machining of individual blades

Machining of turbine rotor

Fitting of blades into rotor

Machining of driven gear

Assembled gears pair